SUCCESS STORY

Dustless Technologies Plays Pivotal Role in Training Future Generations

Josie Gayler’s interest in design and 3D printing started in high school after taking a drafting class where the instructor assembled a 3D printer.

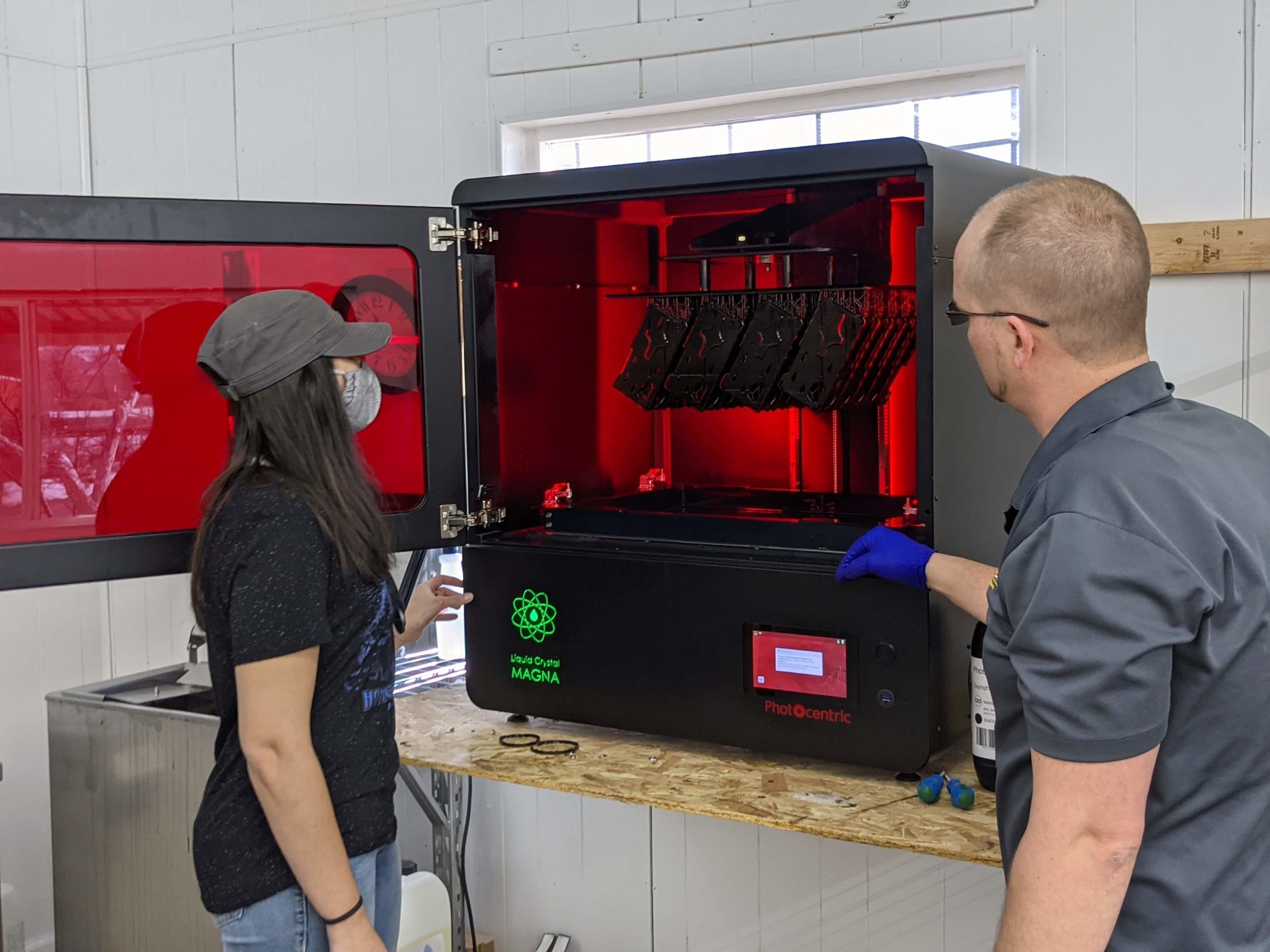

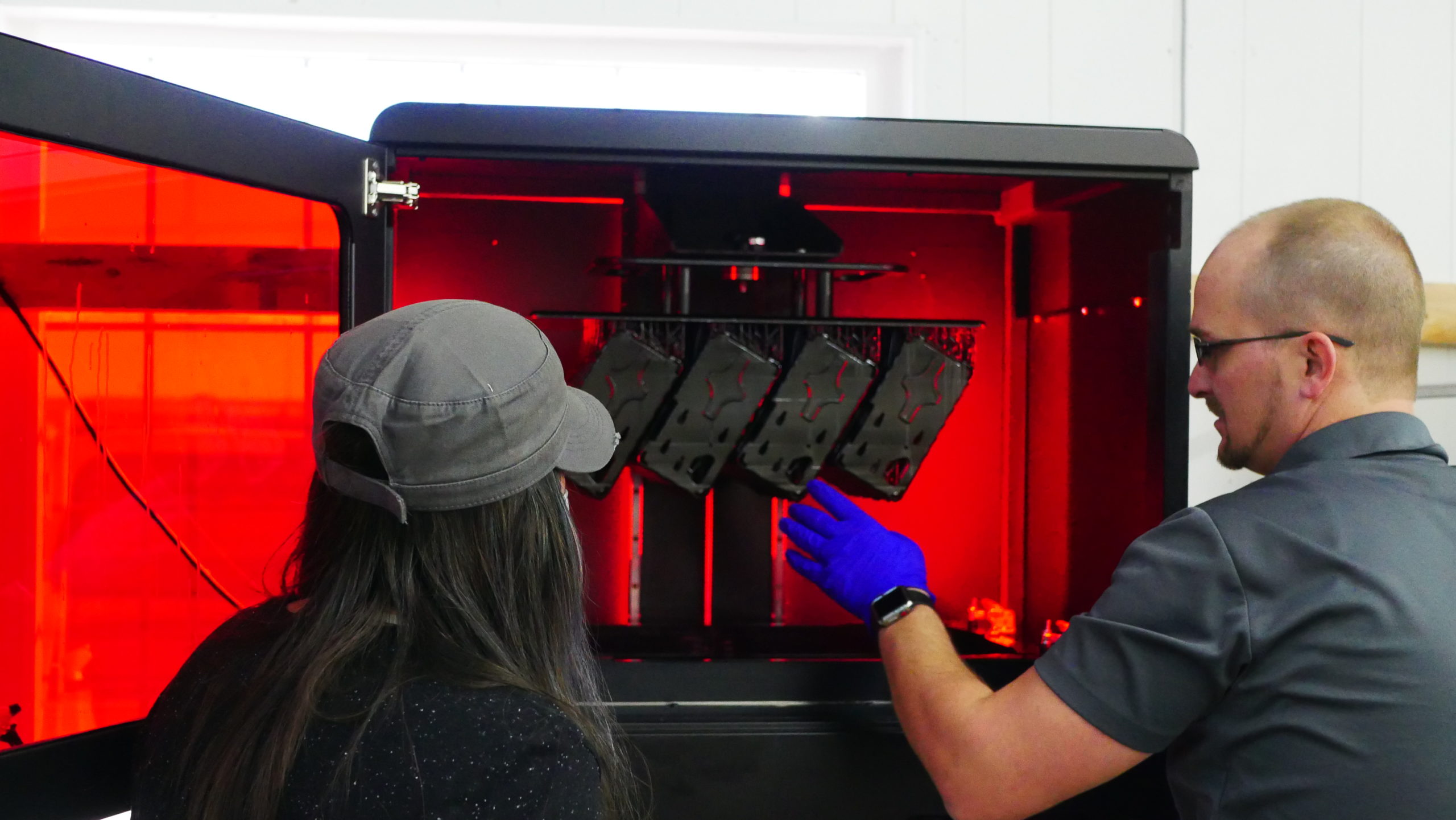

Fast forward a few years, and now she’s expanding her career horizons at Dustless Technologies by participating in training for additive manufacturing. Additive manufacturing, also known as 3D printing, is a transformative approach to industrial production that enables the creation of lighter, stronger parts and systems.

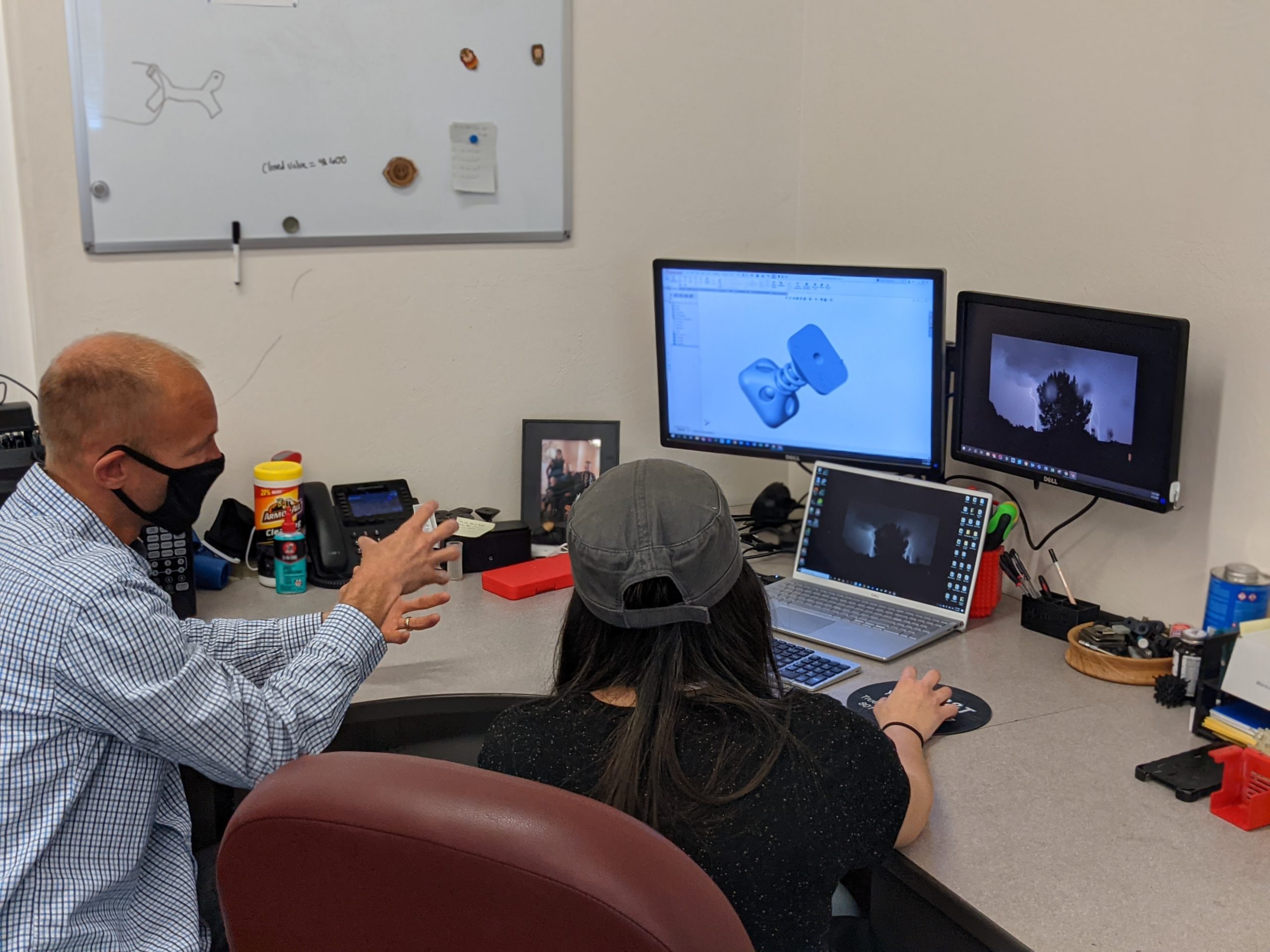

Gayler was one of the students in the new advanced manufacturing course at Utah State University Eastern in Price. “This is the most extraordinary thing I have ever worked on,” said Gayler as she learned Solidworks 3D design. “I made a multi knife with blades, nuts and bolts, and all the components.”

In early 2020, Spencer Loveless took over the reins at the family-owned business, Dustless Technologies, as its CEO and remarked, “There has got to be a better way!” The company traditionally used Chinese injection molding for many of its plastic components for their dust shrouds and vacuums.

“In the last 18 months, we developed methods for bypassing our overseas suppliers through new and innovative manufacturing methods,” he noted. “We are taking a project which usually takes 24 months and getting it ready to sell in four to six months.”

As Loveless and his team grew the additive manufacturing business, they realized there was no training available for their employees, students, or community members. In turn, they approached the Governor’s Office of Economic Development and Utah State University to assemble a program that trains students in advanced manufacturing methods.

“The team at Dustless Technologies has been a solid asset to this community, and we are excited to grow this program using them as one of our manufacturers in southeast Utah,” said Dr. Gary Straquadine, director of the career and technical education programs for Utah State University Eastern.

“There are amazing advanced manufacturing opportunities in southeast Utah that present endless opportunities for individuals like me,” added Gayler.

About Dustless Technologies

Dustless Technologies started in 1985 when Mike Loveless invented the first vacuum to take the ash and hot embers out of a wood-burning stove. He then created a wet/dry vacuum that works on fine dust-like concrete and drywall dust. Further developments were made to invent universal dust shrouds for tools.

The company is on the path to revolutionize the way manufacturers source products. They are starting to bypass their overseas suppliers by using new and innovative manufacturing methods. Their goal is to “3D print” mostly everything from dust collection shrouds to full wet/dry vacuums.

Dustless Technologies has 35 employees and looks forward to expanding and creating more jobs in rural Utah. Its goal is to create an additive manufacturing mecca in southeast Utah with parts from plastics, metals, and carbon fiber. The company also started Merit3D in 2020 to supply these additive manufacturing services to other manufacturers.

Recent Comments